End of Barrel Products

|

|

End of Barrel Products

|

|

EMI began supplying the Plastics industry in 1969 with one small division manufacturing non return valves for injection molding machines. They are now one of the world’s largest manufacturers of end of barrel components, accessories and auxilliary products.

|

|

|

Free Flow: Generous, self-cleaning flow paths minimize residence time, provide excellent screw recovery rates and allow color changes to be made easily. Highly polished radiused surfaces and an exceptionally non-compressive design make it an excellent choice when running shear, compression-sensitive, or fiber filled materials. Standard: H-13 tool steel, nitrided. Optional: 440C stainless steel, CPM 9V tool steel, CPM-T420V stainless steel.

Control Flow: Excellent shut-off capabilities and a compression ratio of approximately 2:1, provide outstanding performance for over 90% of all material applications. Smooth, wide flow patterns and low compression allows shear sensitive materials to be run with ease.. Standard: H-13 tool steel, nitrided. Optional: CPM 9V tool steel, stainless steel or CPM-T420V stainless steel. Four Piece: Five generous flow paths for the melt minimize the risk of shear burning. If the check ring’s front seat begins to wear, that’s all you have to replace...you’re back up and running fast without replacing the whole assembly. For general purpose resins, some engineered and fiber-filled materials. Good screw recovery rates, fast shut off and four times the seating area of a ball check, resulting in more positive seating force. Standard: H-13 tool steel, nitrided.Optional: CPM 9V front seat, ring and seat hardened to R/C 54-56.

Interlocking: EMI’s Interlocking check ring valve is a great design choice for general-purpose material applications. Self-cleaning flow paths provide for quick material changes and the ring rotates with the valve body to aid in reduction of any possible flute wear during processing. Standard: H-13 Tool Steel and Nitrided. Optional: CPM-9V tool steel and CPM-420V Stainless Steel.

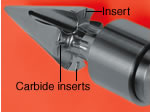

Carbide Inserts: 3 piece, 4 fluted Carbide Insert valves are made of H-13 and features carbide inserts at the base of each flute. Inserts protrude slightly from the flute allowing the inserts to ride against the ring rather than the flute itself - this has proven to be extremely effective in preventing wear in this area (95% of all valve wear is usually seen in the flute area). |

Ball Check Valves Front Discharge: Excellent choice for running non-shear-sensitive, general purpose materials. Low cost, removable ball check inserts can be interchanged for various compressions and recovery rates. Year after year, molders have preferred EMI’s ball check valve because of its dependability and consistency. Standard: 4150 pre-treated steel. Optional: 440C stainless steel or CPM 9V tool steel. Inserts available in S-7 tool steel.

High Flow: EMI Hi-Flow ball check valves feature extra large inlets and flow paths to dramatically increase melt flow while cutting compression ratios down to 1.5:1. Recovery times are cut without sacrificing precision shot control. Included: Includes EMI’s exclusive, low cost, removable ball check insert which is interchangeable for various compressions and recovery rates. Standard: 4150 pre-treated steel. Optional: 440C stainless steel or CPM 9V tool steel. Inserts available in S-7 tool steel.

Side Discharge: This ball check valve gives you excellent shot control, enhanced mixing action, is self-cleaning and purges rapidly via a “washing” action between the nose cone and end cap, making it ideal for fast color changes. Replaceable, low cost ball and ball seat minimize maintenance costs and downtime. Hand seated interfaces ensure a tight seal. This is an ideal valve for general purpose, non-shear-sensitive materials where frequent color changes must be made. Standard: 4150 Pre-treated steel. Optional: 440C stainless steel or CPM 9V tool steel. Accessories: Replacement Inserts: Available in 3 styles to suit specific application needs O.D of Ball Check available in: 1"-2 1/4" (25mm-57mm), 2 5/16"-4" (58mm-100mm), Over 4" (Over 100mm) 4150 Steel, High-Compression, S-7 Tool Steel Ring Valve Wrenches Ball Check Insert Wrenches Brass Rod Kits

|

|

End Cap Systems

Use to process vinyl, polycarbonate, ABS and other low molecular weight materials. Field proven results include a more uniform melt, consistent shot sizes, less scrap, and higher productivity compared to smear tips. Features:

Nozzle Accessories Machine Adaptors: Standardize all your machines to accept standard, stocked 1 3\4"-8 nozzles. - made to your machine thread specifications NEVER SEEZ: Protect cylinder bolts, nozzles, and check valves with anti-seize and lubricating compound. Heater Bands: EMI Heater Bands are ruggedly constructed to deliver long, reliable service. Strong, stainless steel braid protects wiring on sizes up to 1 1/2" x 1'. Leads on larger size Heater Bands are heavy-duty, reinforced fiber glass or post type. Cartridge Heaters: EMI Cartridge Heaters are quality made for long life and precision fit. Reinforced leads protect wiring, providing a dependable heat source for your cartridge heater applications. Nozzle Thermocouples |

Nozzles

If you’re molding large, high-ounce capacity parts, the EMI Big Bores will give you dramatically improved flow area! Featuring a 3\4" I.D. bore size versus 1\2" standard units, providing higher throughput.

Shut Off Nozzles

EMI Performer Shut-Off Nozzles help optimize molding machine productivity by allowing the screw to retract while the mold is opening and closing. You’ll shave cycle times to a minimum and increase fill rates for high speed or large part molding. Positive, air operated pin closing allows faster screw recovery and stops drool in its tracks.

|

One Piece Nozzles

One Piece Nozzles Two Piece Nozzles

Two Piece Nozzles Big Bore 2 Piece

Big Bore 2 Piece  Internally Heated Nozzle

Internally Heated Nozzle