|

Definition and description of Process;

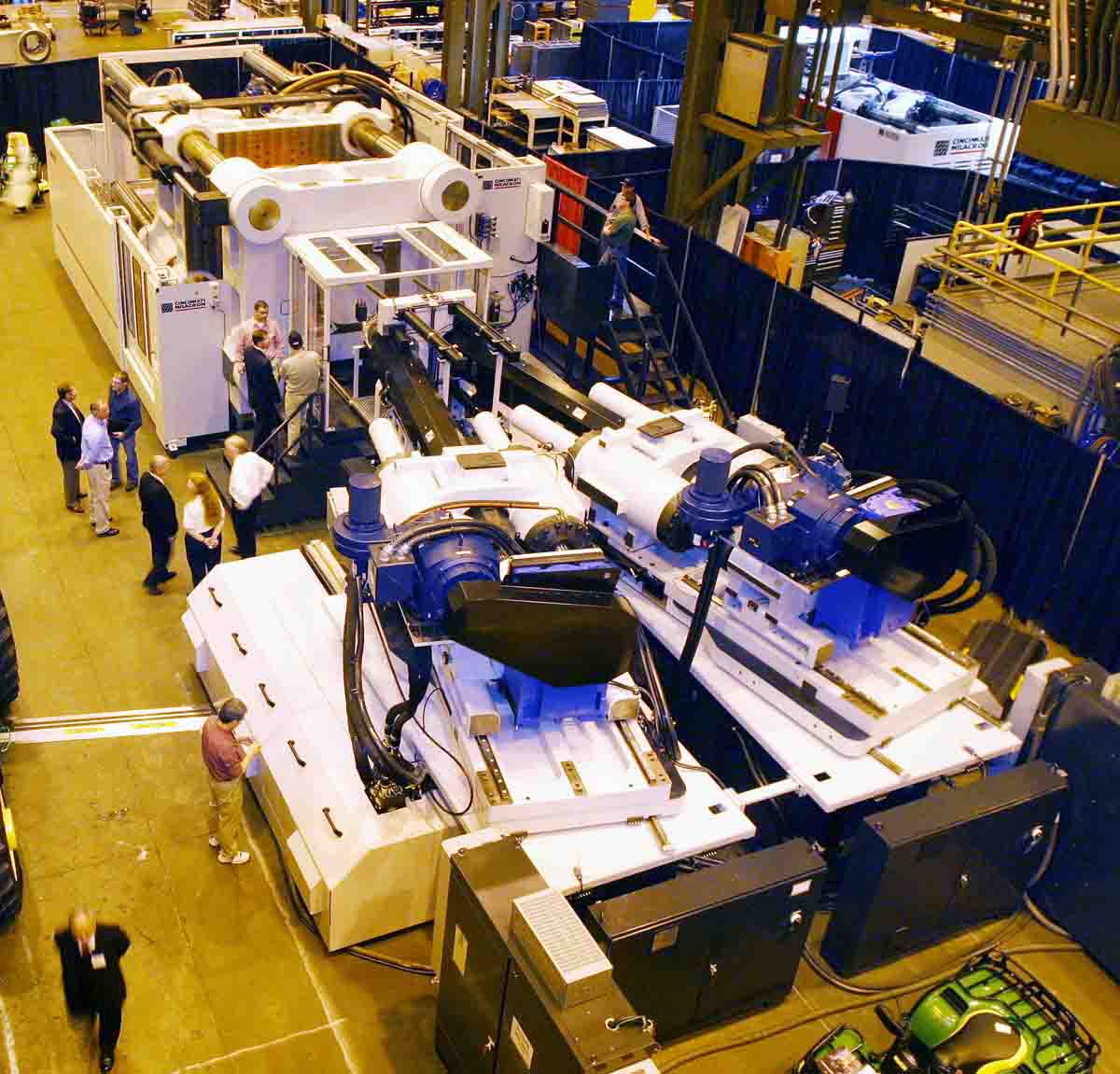

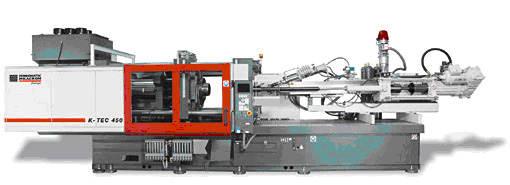

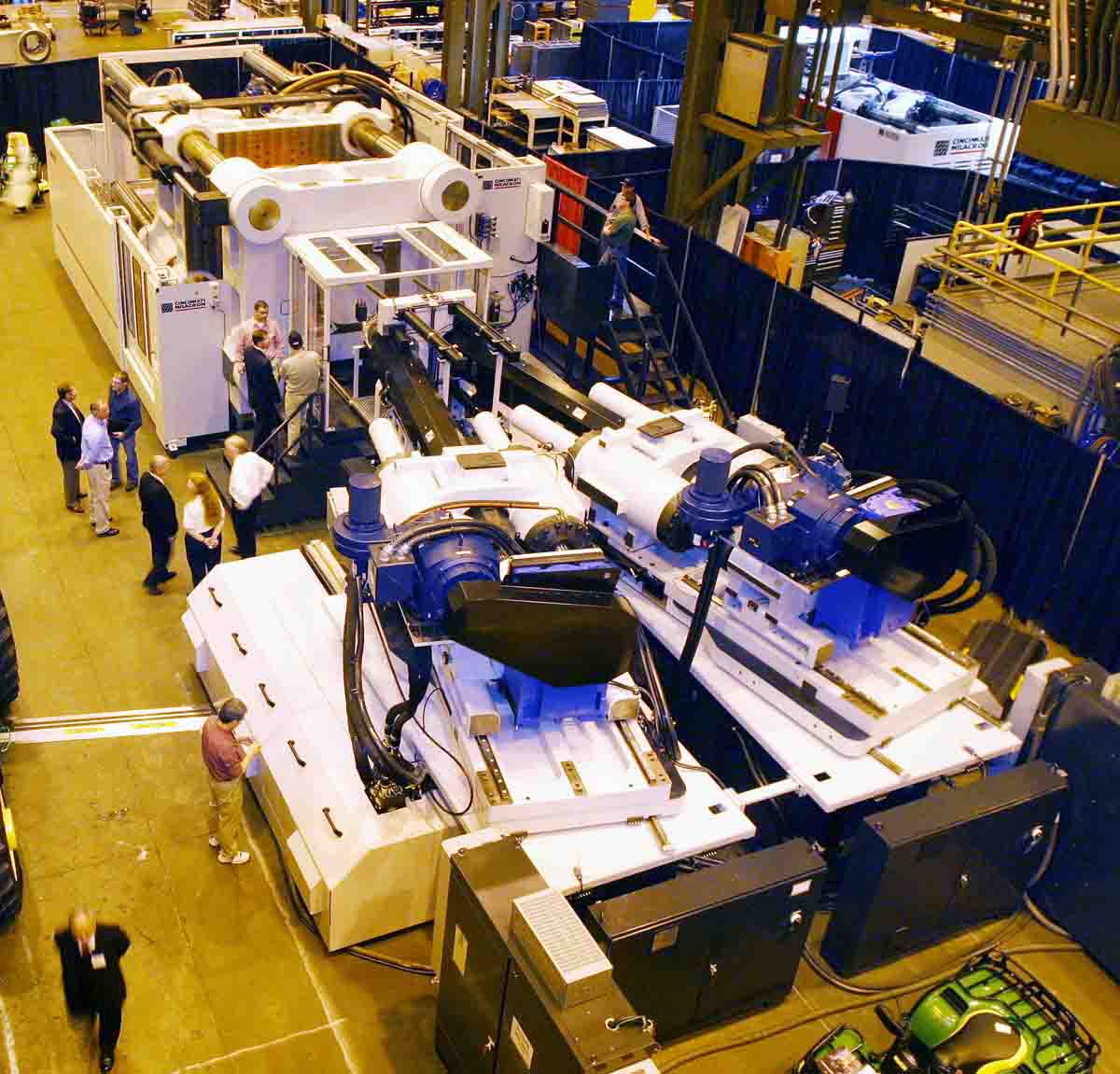

Multi-component injection molding machines features the same features as a standard molding machine but includes an additional injection unit (or units) to enable the molder to mold multi-color or multi-material parts within a single molding machine cycle. Typical multi-colored parts have been electronic switches, keyboards keys, covers, etc. Typical multi-material parts use materials known for strength along with other materials which exhibit elastic properties.

Some Possible process variations;

-Multi-color – same materials but with different color

-Multi-component with compatible materials, i.e. plug connections, rollers, sealing covers, soft touch materials over hard.

-Multi-component with incompatible materials, i.e. joints, hinges, etc. - Co-Injection - Or Skin Core Skin: Encompassing a core material with a secondary skin material.

-Handling – moving the parts from cavity to cavity via robot, i.e. automotive vents, handles, etc.

-Core back – molding a second material by retracting core pins, i.e. cassette case

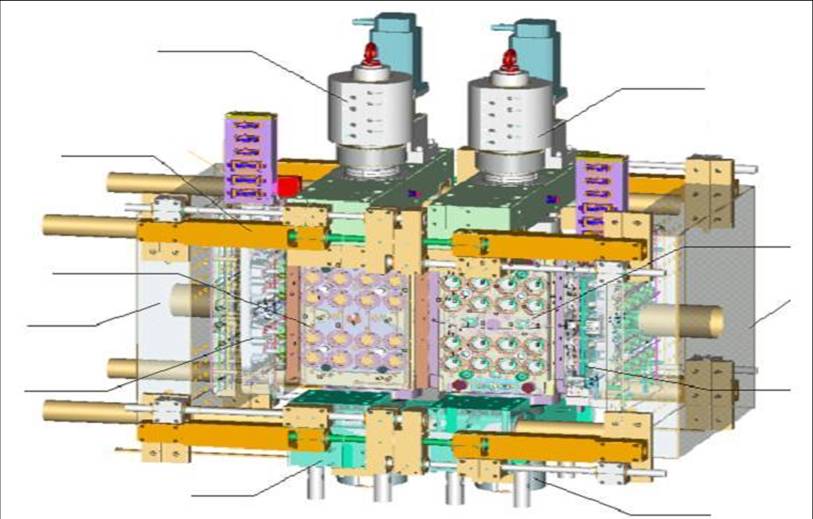

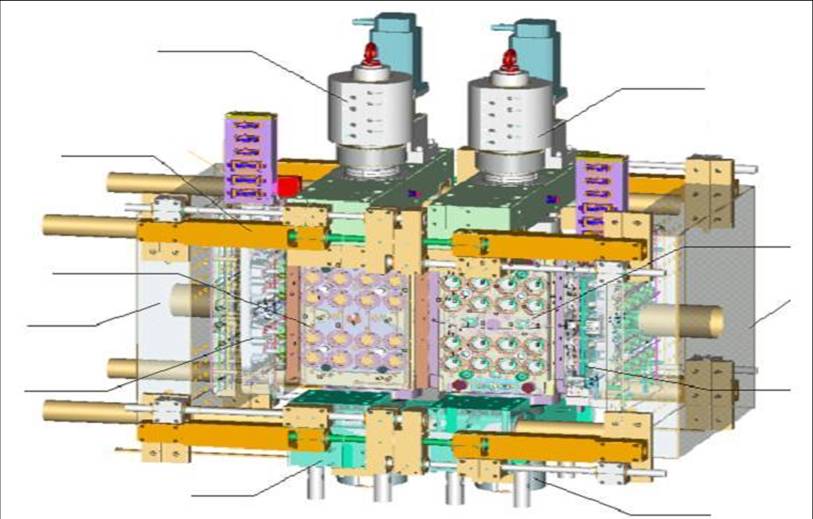

Rotary Platen (Windows Video)

Spin Stack Cube, Double Cube...(Windows Video)

Milacron has the experience for multi-color / multicomponent applications in Press sizes ranging from 55 - 6600 tons clamping force. New or Retrofit.

|

Benefits to customer;

The main and the additional injection unit(s) function can function either sequentially or independently of one another

Molding multi-color parts.

Molding parts composed of both rigid and soft materials.

Machine can still be operated as a single component machine.

Orientation of vertical injection unit can be adjustable along the longitudinal axis of the machine for adapting to the mold.

Orientation of "L" arrangement - with the second injection unit located on non-operators’ side of machine – also allowing adjustment along the longitudinal axis of the machine.

The "Process Control" can be controlled the same as traditional injection molding.

Contact us for more information and success stories.

|